Add to Cart

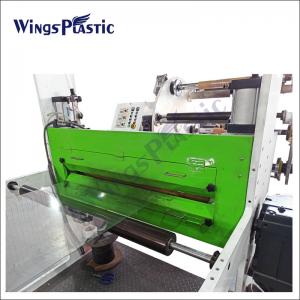

PET Sheet Making Machine PET plastic transparent acrylic Clear rigid sheet Making Machine

PET sheet extrusion line classification:

1. PET sheet single screw production line: APET, PETG, CPET sheet single screw extrusion line is the current mature process, stable production program, generally using single or double machine co-extrusion form, we uses new technology, so that the overall efficiency of this model increased by 30%

2. PET sheet single screw exhaust production line: This model only needs to crystallize PET, and does not need to dry. Its advantages: low energy consumption, simple process, convenient equipment maintenance.

3. PET sheet single screw exhaust production line (free crystallization drying) : The free crystallization and dry exhaust PET sheet unit introduced by Wensi has the advantages of low energy consumption and high efficiency. This model is a continuous improvement and upgrading product of Wensi Company. The core vacuum system has been significantly upgraded from the original Roots-water ring pump group to the Roots-rotary vane pump group, which can make the vacuum degree reach ≤10Pa. At the same time, PET professional alloy steel thin-wall roller set is used to greatly improve the cooling efficiency, thereby increasing the output, improving the toughness and transparency of products. Kingwell's independently programmed operating system ensures that the device is user-friendly and easy to operate.

4. PET sheet planetary multi-screw exhaust production line (free crystallization drying) : The use of planetary screw extruder as the host, to increase the area of material and air, with the newly developed vacuum system of Kingwell, can meet the needs of large output, high-quality sheet customers.